With the Screamin’ Woody finally reassembled after a two year tear down from the Texas Whale and rebuild to the Screamin’ Woody, it was time to take it to the track. Normally I’d take it to San Antonio Raceway, a 1/4 Mile track about 200 miles away), but I was really Jonesing after missing Norwalk and Joliet, and the Indy race was coming up.

SHRA had an 1/8-Mile NSS Race in Denton (350 miles) on the 14th. While further and only 1/8 mile, it would help support NSS Racing (which is weak in the South) in Texas and give me competition practice. So I loaded up on Friday night and left for Denton early on Saturday morning. I arrived at the track at 1 pm, unloaded and got ready for the driver’s meeting at 3 pm. It was 98 degrees at 3 pm.

First Qualifying was at 4 pm. I launched the car but it didn’t pick up the front wheels (like it use to) and carry the front end, but worst the that, the motor started to break up so I shifted. It quickly started to break up again – so I shifted again. It didn’t break up crossing the line, so I made a mental note that had to be in the 6000-6500 rpm range. Back in the pits, I only had time to cool the car down, put a charger on it, log the run, change tire pressure, and adjust the 5 point harness – which needed a foot taken out of the shoulder length.

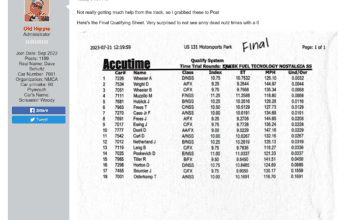

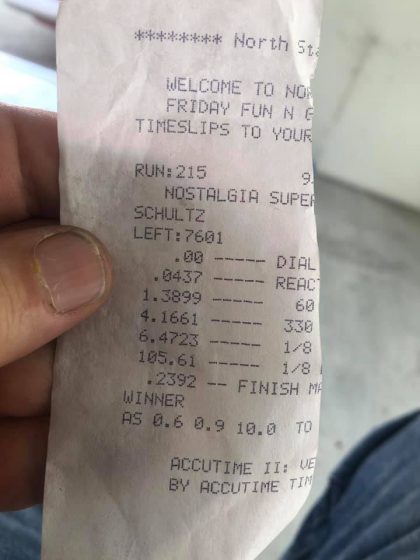

At 5 pm, just as I was finished with harness and we were called for last qualifying. I told myself that this pass I’d stare at the tach to figure out at what RPM it was breaking up. I dropped the slick’s pressure a 1/2 pound, launched at 2000 RPM, and starred at the tach. It started to breakup at 6300, and I shifted immediately. Again it broke up at 6300 and I shifted to third. I don’t have that time slip, but the 60′ improved slightly to low 1.38 and ET was 6.34.

Back at my pit, I got car ready for first round of Eliminations and did some Basic looking around to figure out why it was breaking up, and couldn’t see it. I had declared the 6.25 Index, and was hoping it might get cooler and I’d find the problem. It didn’t get cooler (95 degrees at 6 pm) and I didn’t find the problem – so I set my shift light at 6200 (normally 7200-7300 on a 572-13 head motor) and dropped the slicks another 1/2 pound psi.

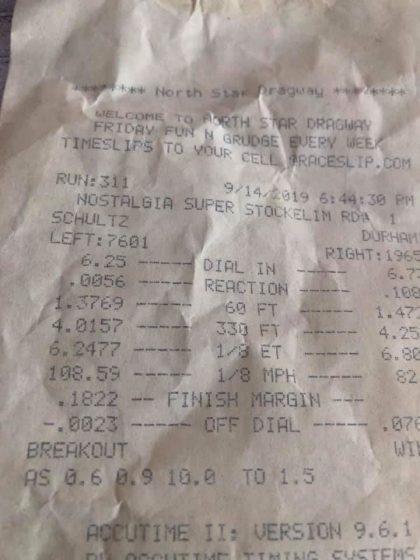

I was racing a slower car who would leave 3/4 second ahead of me. I was convinced that there was no way I could run the number (6.25), and would have to cut a great light for any chance. I got my wish with a .005 light, but my inexperience with the 1/8 mile stripe cost me when I took too much Stripe with a 6.248 ET on a 6.25 Index, or 2/1000 of a second too quick. My 60′ was a little better with a high 1.37. The car did not break up with me shifting at 6200.

So I loaded up and was heading south by 7:30 pm, arriving back at the shop at 1 am Sunday. Other than the breaking up and launching with left front higher than right front, I was relatively happy with how the car performed, considering everything being new. On Monday, I backed the car out of the trailer, replaced the Distributor Cap and Rotor (both of which looked new), check all of my wiring to the plugs, and all wiring going to the MSD 7AL2 ignition box. I noticed that the box had 7000 rpm pills in it, and remembered reading that the pills (working by having their Ohms read and converted to a Maximum Limit of RPM allowed) can be off by as much as 10%, which 700 RPM, which subtracted from 7000 = 6300. I changed them out to 8000 RPM pills, which really should have been there in the first place. I put the car back in the trailer, and loaded spare parts consisting of a spare ignition box, spare distributor, spare set of plugs, and new set of wires.

Tuesday at 4 am I left my shop in Beasley, TX and arrived at my bud Doug Duell’s Mother’s house (Southern Indiana) at 6 pm. I dropped the truck and trailer there. Doug and Anne took me to dinner and put me up for the night. In the morning Doug took me to look at the new house that he’s building, and then to his dealership for me to look at the Palisades Limited, which I’m interested in a pair for Deb and I. At 9 am he took the lead with his motorhome and stacker, as I followed him in my dually and trailer. We had a little delay due to a Turbo issue on his coach. We got on the track at about 5, and I was at the hotel by 6.

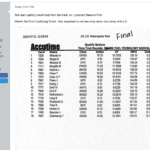

I arrived at the track at 9 am, paid my entry, got car out of trailer, established credentials, got my chassis certified, teched the car in, and made it ready for the first 1/4 mile hit since being built. We checked the car’s timing, I charged up the dual 16v batteries, created a new weather station database for the car, and at about 1 pm (this is Thursday now) they called us for the first time trial. The car had an unimpressive 9.99 and 1.38 short time. Worse yet was that there was oil all over the front of the car, and another racer told me that I dropped a part at the line. I opened the hood and found the AN-12 Screw on plug for the oil filler was missing. I went to the starting line, and it was in the trash can, mangled an unusable. I couldn’t figure out how it could make six 360 degree turns and blow off – but it did. This would become understood later. I bought another fitting, screwed it on, and used electrical tape stretch around cap & bung to hold it on. I spent the next hour wiping the car down underneath of all of the oil. When called for next time trial, and after my burnout – I was backed up and off the track with them saying I was leaking oil.

I went back to the pits and spent three hours under the car wiping up oil and trying to figure out where three mystery leaks were coming from. I finally got under the car with it running and only then did I see weeping from the oil pan gasket — which the engine builder had used grey Permatex to make. Many of the oil pan nuts were loose – and I snugged them down. Just as I was lowering the car — the track announced a clean up session for those who didn’t get two test hits — and I hustled off to it.

After I came out out of the burnout area I had all of the track people looking under the car for any drip. They cleared me and I pre-staged, Staged and took off. All was going well until the 1000′ when I looked in the mirror just as the car started smoking. I immediately pulled over and off the track’s first exit. Off the track I found I was leaking oil all around the oil pan. It was late and I was both worn out from working all day in the heat and sore to where my back and shoulder were killing me. I was going to throw in the towel for the day and try to deal with it in the morning — but Jeff Frees talked me into dealing with it that night.

Long story short, Doug Duell drove the car onto Jeff’s lift, Jeff and his crew started to tear the car apart, I drove to an all night auto parts store in Indianapolis for a couple of gaskets, and I was back at the motel by midnight. I was back at the track at 6:30 the next morning to clean up the car and make ready for the First Qualifying at 8:30 AM. I took it for a ride to blow off any extra oil that I might have missed off the car, and gave it a final check. All looked good.

So they call us for the first qualifying hit — and that’s when we noticed that oil was under the car again. Again to make a long story short, my vacuum gauge in the car wasn’t working and Jeff came over with a manual vacuum gauge to take a reading and adjust in more vacuum to slow the leak, so I could make the pass. That’s when we got the puzzling gauge reading of positive pressure instead of vacuum. It was too late to make a hit — so I got out of my racing suit and headed over to the car to disconnect the vacuum pump for Q2. While Brent Wheeler and I were looking at what was needed to disconnect — we both, at the same time, realized the hoses had been installed backwards. While both hoses were the wrong length to be properly swapped around — they did fit for a temporary fix. I did that and made it in time for the second Qualifying — which appeared to be good — albeit slower than expected.

The next round was the first round of class eliminations for FX. There was a couple grand on the line — including $1600 in side bets to the winner. I was matched up against Dan Cook, who was the faster car by 1/4 second. Car felt good on that pass, and I saw the Win Light for me – but when I picked up the time slip I found that I’d run a 9.9 on a 9.75 Index and only won because Dan had a really bad light. Worst yet, after I picked up the ticket — I started hearing a noise that sounded like valve train clatter. I still had oil pressure but the motor didn’t sound right. In the pits, dozen’s of people were coming by to give their opinion and advice. After the valve covers came off and on three times — I was done and parked the car in the trailer.

I returned to the track the next day to be a spectator and attend that evening’s Dave Duell Classic Dinner. I left the track at about 10 pm with my truck and trailer, got a little sleep and left the motel at 4 am. I arrived at my shop (1125 miles later) at 11 pm.

In the shop, we first thought that the noise was from a couple of rockers rubbing on the valve cover. The valve covers were clearanced and we still could hear the noise/ With a stethoscope it sounded like it was coming from under the valley pan – lifters suspected. When the lid to the valve cover was removed, it was noticed that pools of race gas had formed in the damned off areas. A witness mark showed that the levels were as high as 3/4″ before draining through the bolts holes into the motor. Draining the oil found a lot of gas in the oil, which only had two runs on it. A shop rag dipped into the oil more closely exploded than burned when a match was put to it. It was decided to pull the motor. There are some issues. A puzzling one is that the rods and crank bearing surfaces appear to have been contaminated and have specs on them. We’re assuming from the race gas. So that’s where we’re at with the wagon as I write this.