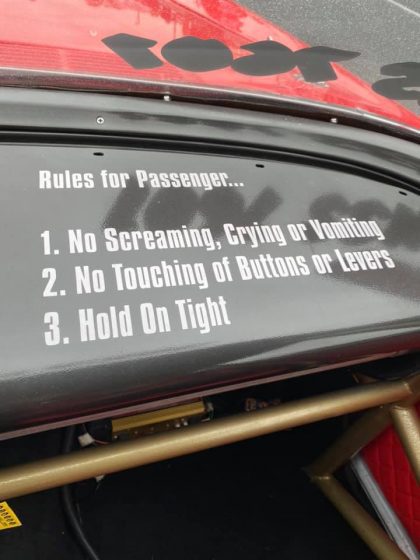

Since the motor in the wagon had been untested, I first put the Texas Thug on the Lift of the stacker trailer, and the Screamin’ Woody under it. If the wagon couldn’t make the call, then I would have raced the Thug. 1100 miles is too far to go with an untested car unless you have a backup.

So Deb and I; Smiff and Wesson (our Toy Schnauzers); and our two new 9-week old Black Lab puppies – Ole Black Bettie and Billie Sue left Sunday early and got as far as the NASA rest area in Mississippi. Monday night we arrived at the track, and spent the night outside the gate. Tuesday we got onto the track and set up the pits.

Wednesday you could rent the track for $250, which I did and got three hits in. The first run, off the trailer was a very slow 10.1, breaking up a little as I crossed the line. I turn up the fuel pressure a little and made a 9.89 pass without breaking up. I and a couple Buds started looking around to see what was wrong – and found the timing was set at 30 degrees. Set it to 36 and I went up for a third hit. The car wouldn’t start, despite my volt gauge saying 17 volts. I got towed back to the pits and thrashed on the car – swapping the newer pair of 16V batteries from the Thug to the wagon. It was a time consuming process as the wagon was set up wrong – having the batteries hidden behind the weight boxes. It took about 2 hours before I could get back in line just as last call was made. I managed a 9.69 @ 139MPH.

Thursday, there was another Test & Tune, but I didn’t take part in it, as I felt my car was where I needed it. I instead spent the day polishing the car, cleaning up the trailer and playing with puppies.

Friday we were given a time trial and two Qualifying hits. On the Time Trial I was feeling pretty confident when I did my burnout and staged. When the lights went Yellow I launched, and then the car fell flat on its face. I pulled to the wall and looked at oil pressure, it was good so I looked in mirror. I saw no smoke nor did I see a trail of liquid, so I continued idling along the wall. I had no accelerator response and looked at fuel pressure and it was a steady 3psi (when I run 7psi) – so I continued to move up track, trying to get off without the tow of shame. At about the 660′ the fuel pressure went to 1 and I shut the car off. The track’s 4-wheeler with a slick roller pushed me off the track. I tried to start the car, it started, I had fuel pressure, and I drove back to my pit.

In my pit I checked all electrical connections. I couldn’t find any loose connections, or duplicate the problem.

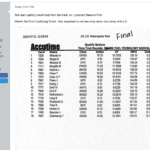

The next run was the first Qualifying. I loaded up with a ton of weight. The car launched with a Monster Wheel Stand and ran great until a few feet before the finish line, where it broke up just before I lifted. Below is the time slip.

As was making the turn off the track, I noticed my fuel pressure was a steady 3psi. I pulled over, shut the car off, restarted and was back to my 7psi.

Back in the pits I changed the fuel regulator, thinking I had some scumotes in it, which would backwash when I turned off power.

In the early evening I loaded up the maximum weight, as I was too fast in the first Qualifying. In the Staging Lanes, I showed 0 Fuel Pressure when I started the car to move into the Burnout Box. I shut car off and restarted and I was good. That weight had me doing a giant wheelstand and the car ran good down the track.

Done for the night, but obviously having an issue still, I changed the relay switch and disassembled the new filters to inspect and clean. They looked as clean as a whistle, so I doubt they were the issue.

This is where I need to give a shout out to Fuelab. In 2013, the year before I won the Championship, they sponsored me with product. I’ve used about every brand of fuel system and Fuelab was the best I’ve ever used. After winning the Championship I had a couple of bad years because of health, motor problems, and both of my in-laws (who we were taking care of) dying. You have to win to keep sponsors, and understandably, I lost the few I had, including Fuelab. That said, I bought and continued to use Fuelab rather than seeking sponsorship elsewhere. So while I was having these Fuel issues, Josh was following me on Facebook and reached out to offer any help he could give – and I really appreciate that. While I’m now convinced that my problem was the electric relay, Josh has invited me to send my regulator and fuel pump to him for testing – just make sure. I’ve just bought a spare as I’ve always (until the last few years) carried a spare – regardless of brand.

Feeling confident that I had my problem fixed, I put the car away for the night. Saturday morning Q3 was very early and a cold 45 degrees. I had the maximum weight in the car and the weather station said I’d be a 1/4 second too fast. The car didn’t pick up the wheels as high as Normal, but sounded and felt good going down the track. However, the time skip told a different story with me a 1/4 second too slow and a horrible 60′.

Back in the pits, the timing was rechecked and fine. Everything I could think of was checked, and I couldn’t find a problem. I wrote it off as being one of those unexplainable mystery runs – like tire spinning.

Saturday night was my final qualify hit. Again the launch sucked, as did my time slip and 60′.

Back in the pit, Doug Duell sprayed foaming window cleaner on each of my header tubes as the car ran, and found #8 hole dead. I replaced the wire, retested and found that it now had fire in the hole.

My crappy #11 Qualifying matched me up with Barry Dorn in the first round. I was convinced that the car was fixed, but again it was so cold that I was bagging a 1/2 second faster than my index. He too was fast as he was the last qualifier, because of breaking out on all four Qualifying passes. My strategy was to figure out if I wanted the Stripe or give it away when I got there. However, the car ran like it was stuck in mud, off more than 1/2 second too slow. As I was loading the car onto the trailer, we again sprayed foaming window cleaner on the header tubes and now #4 hole was dead.

We loaded up and was off the track by noon – driving about 600 miles to spend the night at a sketchy Walmart in Mississippi. Monday we finished the final 500 miles arriving home in the early evening. Tuesday, the car was unloaded and valve covers removed. It was found that the intake rocker number 4 backed off and the push rod went between the rockers – tearing push rod and rockers up. I ordered a new pair of rockers

While it would have been nice to have had things go smoother for first race of the year, this is both a new (rebuilt from ground up last year) car and motor. These things happen when you don’t have time to test locally.